Production Lines

The cutting line is equipped with advanced machinery such as laser cutters and plasma cutting systems, ensuring high precision and efficiency in material preparation. This step is crucial for achieving the exact dimensions required for subsequent manufacturing processes. The use of automated cutting technology minimizes material waste and ensures consistency across all components.

The welding line features state-of-the-art welding technologies, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, as well as automated welding robots. These technologies ensure strong, durable, and high-quality welds that meet stringent industry standards. The line is designed to handle complex welding tasks with precision, ensuring the structural integrity of the final products.

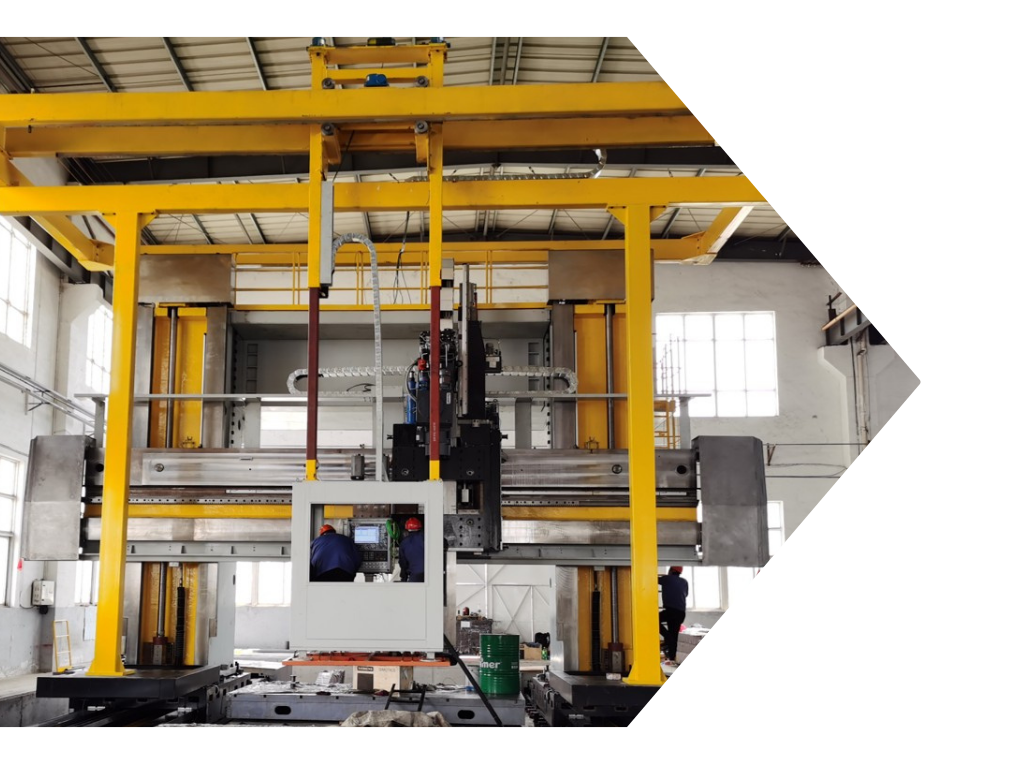

This line encompasses both rough and finish machining processes, utilizing high-precision CNC (Computer Numerical Control) machines. Rough machining removes excess material to shape the components, while finish machining achieves the exact dimensions and smooth surfaces required. The integration of CNC technology ensures high accuracy and repeatability, critical for producing high-quality parts.

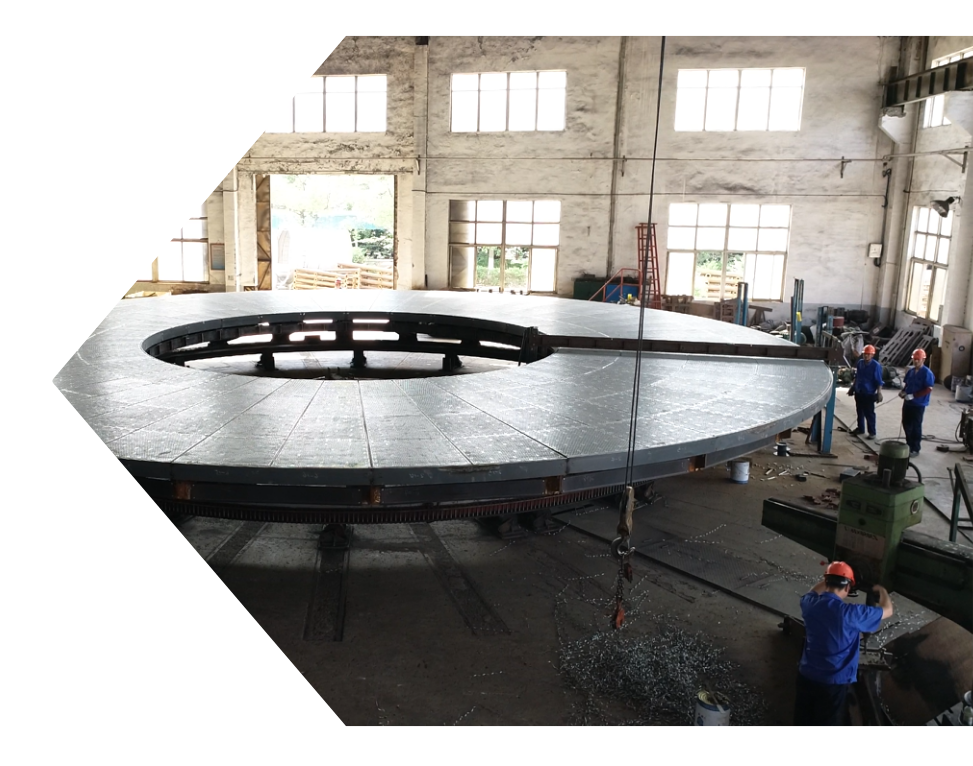

The fabrication line integrates advanced technologies for shaping and assembling components. This includes press brakes, rolling machines, and automated assembly systems. The line ensures that all fabricated parts meet precise specifications and are ready for final assembly. The use of automated systems enhances efficiency and reduces the risk of human error.

The assembly line focuses on the meticulous assembly of fabricated and machined parts. Automated systems and robotic arms are used to ensure consistency and accuracy in the assembly process. The line is designed to handle complex assemblies, ensuring that all components fit together perfectly and function as intended. Quality checks are integrated at every stage to maintain high standards.

The final stage involves rigorous testing, commissioning, and start-up procedures to ensure each product meets 100% quality standards before delivery. This includes pressure testing, functional testing, and performance verification. The line is equipped with advanced diagnostic tools and testing equipment to ensure that all products are fully operational and meet client specifications.