NHD possesses world-class CFD fluid design software FLUENT and operates China’s leading pilot-scale mixing simulation test platform along with a provincial-level laboratory.

Our extensive expertise in fluid mixing, supported by optimal application design software, proprietary mixing theories, and robust laboratory analysis capabilities, establishes us as the preferred supplier for fluid mixing equipment.

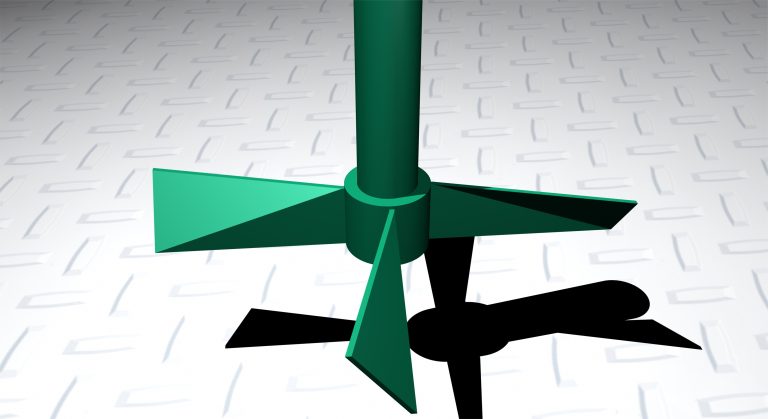

In PA reaction tanks, the co-current agitator generates force in nearly the same direction as the fluid flow. This design, combined with low surface concentration gradient, significantly reduces gaseous corrosion and shaft fouling.

The agitator blade is engineered based on optimal positioning in the speed-critical zone. Despite having smaller blades than PBT agitators, it delivers superior performance. Furthermore, its compact critical zone diameter and slower radial current minimize tank wall damage, thereby extending the reaction tank’s service life.

Competitive Advantage:

NHD possess a complete range of agitation test equipment capable of meeting experimental requirements for different manufacturers and processes, including: lab-scale tests, pilot tests, and scale-up experiments.

Advanced R&D Technologies:

NHD can conduct customized agitation experiments based on customers’ specific material requirements, providing solid theoretical foundations for agitator design and selection. Leveraging over two decades of design and manufacturing expertise, we deliver optimal technical solutions tailored to each client’s needs.

Selection Input Requirements:

General Product Information

| Place of Origin: | Jiangsu |

| Brand Name: | New Hongda |

| Certification: | SGS, ISO |

| Model Number: | / |

© All Copyright 2025 by Jiangsu New Hongda Group Co.,Ltd.| Privacy Policy