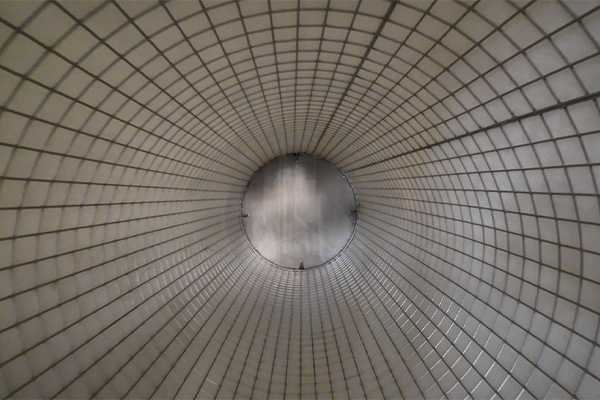

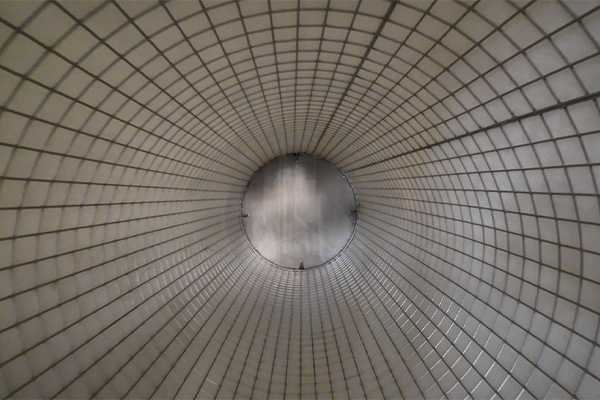

BECOFIL candle Filter is a kind of high efficiency and low pressure loss equipment, it can be widely used in seawater vapouriser, compressed air system, gas emission system, distillation tower, knock-out drum, scrubbing tower, packing tower etc.

In 2005, NHD began collaborating with Begg Cousland to assemble BECOFIL candle filters. While core components are still imported from Begg Cousland, NHD ensures the quality matches the original imported filters.

The headquarters of Begg Cousland Company is located in Glasgow, Scotland, with a history of more than 150 years. Begg Cousland specializes in the design & manufacture of Mist Eliminators, offering a broad range of wire & fibre-based products for industrial air pollution control and in-process filtration. Begg Cousland is the only licensed manufacturer of fiber candle filters by ICI, and supplied 99% of non-wet candle filters for Lurgi Company.

To date, Begg Cousland has hundreds of applications worldwide, and its BECOFIL candle filter has been continuously improved. The fibers used in the filter can be as small as 7 micrometers and are directionally arranged through a special process to remove micro-sized mist, meeting industrial emission requirements. Begg Cousland designs filters based on specifications such as capacity, pressure loss, and efficiency.

برنامه ها:

مزیت رقابتی:

| مدل | Efficiency | Process Parameters | Remark | |

| Pressure Loss (mm H2O) | Bed Velocity (m/s) | |||

| TGW15 | 100% > 1 μm | 37~225(Dry) | 0.05~0.25 | Highest Efficiency |

| 98% 0.5-1 μm | 75~450(Wet) | |||

| B14(W) | 100% > 3 μm | 78~335 | 0.1~0.35 | High Efficiency |

| 98-99% < 3 μm | ||||

| G25 | 100% > 3 μm | 12~400 | 0~2.5 | High Capacity |

| Note: Besides the above common glass fibers, there are Polypropylene fiber PP13.5, Polyester fiber PT12, Teflon fiber T80.35, Carbon Fiber C14 for mist or particles removal in special processes. | ||||

General Product Information

| محل مبدا: | جیانگسو |

| نام تجاری: | New Hongda, Begg Cousland |

| صدور گواهینامه: | SGS ، ISO |

| شماره مدل: | / |

© All Copyright 2025 by Jiangsu New Hongda Group Co.,Ltd.| Privacy Policy