Vertical Automatic Press Filter

Introduction of Vertical Automatic Press Filter

HDLY Automatic Vertical Press Filter is developed by NHD on basis of assimilating technology of press filters domestic and abroad with wide applications in non-ferrous, smelting, chemical, coal beneficiation, food ,porcelain, paper, sugar, dye, waste water treatment by washing, filtering, dewatering to separate solid from liquid.

1. Features compared with Frame Filter Press:

1) Large capacity, high automatization; 6 processes filtering, squeezing, washing, 2nd squeezing, drying and discharging are all control automatically and continuously, which is 6 times of frame filter press.

2) Low water content in cake. Since the pressure can reach 1.6Mpa and the cake dry by air, the low water content cake can be made. The water content can reach less than 10% without considering crystal water, and even the traditional dry process can be canceled to save energy.

3) Washingprocess is added with good effect. Cloth can be used for filtering with top and back surface alternating and have a high recovery ability. Cake is uniform with thickness 45mmat maximum.

4) Compact structure. Since it is of 4 vertical column structure with less area. Less or no invest is needed during revamping.

5) The equipment is controlled by panel automatically with self-diagnosis and alarm system.

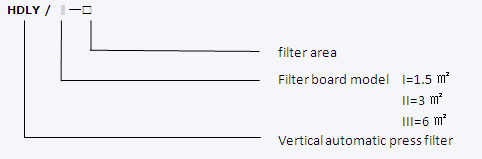

2. Press filter model

Model mark:

Automatic press filter is developed further on squeeze principle. Its main processes contain feed-in, DiaphragmSqueeze, washing and airdrying.

The pressure filter can be divided into according to process:

A. Short Processes

There are 4 processes (filtering, squeeze, drying, discharging) without washing.

B. CompletedProcesses

There are 6 Processes (filtering, squeeze 1, washing, squeeze2, drying, discharging).

3.Technical Description

|

Model

|

Filter Area(m2)

|

Dimension m

(L×W×H)

|

Plate Qty.

|

(MPa)

Max Pressure

|

|

HDLY/Ⅰ-6

|

6

|

4.7×2.7×2.4

|

4

|

1.6

|

|

HDLY/Ⅰ-9

|

9

|

4.7×2.7×2.6

|

6

|

|

HDLY/Ⅰ-12

|

12

|

4.7×2.7×2.8

|

8

|

|

HDLY/Ⅰ-15

|

15

|

4.7×2.7×3.0

|

10

|

|

HDLY/Ⅰ-18

|

18

|

4.7×2.7×3.2

|

12

|

|

HDLY/Ⅰ-21

|

21

|

4.7×2.7×3.4

|

14

|

|

HDLY/Ⅰ-24

|

24

|

4.7×2.7×3.7

|

16

|

|

HDLY/Ⅰ-27

|

27

|

4.7×2.7×3.9

|

18

|

|

HDLY/Ⅰ-30

|

30

|

4.7×2.7×4.2

|

20

|

|

HDLY/Ⅰ-33

|

33

|

4.7×2.7×4.5

|

22

|

|

HDLY/Ⅰ-36

|

36

|

4.7×2.7×4.7

|

24

|

|

HDLY/Ⅱ-42

|

42

|

6.2×3.2×3.8

|

14

|

1.6

|

|

HDLY/Ⅱ-48

|

48

|

6.2×3.2×4.0

|

16

|

|

HDLY/Ⅱ-54

|

54

|

6.2×3.2×4.2

|

18

|

|

HDLY/Ⅱ-60

|

60

|

6.2×3.2×4.5

|

20

|

|

HDLY/Ⅱ-66

|

66

|

6.2×3.2×4.7

|

22

|

|

HDLY/Ⅱ-72

|

72

|

6.2×3.2×4.9

|

24

|

|

HDLY/Ⅱ-78

|

78

|

6.2×3.2×5.1

|

26

|

|

HDLY/Ⅱ-84

|

84

|

6.2×3.2×5.3

|

28

|

|

HDLY/Ⅱ-90

|

90

|

6.2×3.2×5.6

|

30

|

|

HDLY/Ⅱ-96

|

96

|

6.2×3.2×5.8

|

32

|

|

HDLY/Ⅲ-108

|

108

|

7.2×3.7×4.5

|

18

|

1.6

|

|

HDLY/Ⅲ-120

|

120

|

7.2×3.7×4.8

|

20

|

|

HDLY/Ⅲ-132

|

132

|

7.2×3.7×5.0

|

22

|

|

HDLY/Ⅲ-144

|

144

|

7.2×3.7×5.2

|

24

|

|

HDLY/Ⅲ-156

|

156

|

7.2×3.7×5.5

|

26

|

|

HDLY/Ⅲ-168

|

168

|

7.2×3.7×5.7

|

28

|

|

HDLY/Ⅲ-180

|

180

|

7.2×3.7×6.0

|

30

|

4. Work principle

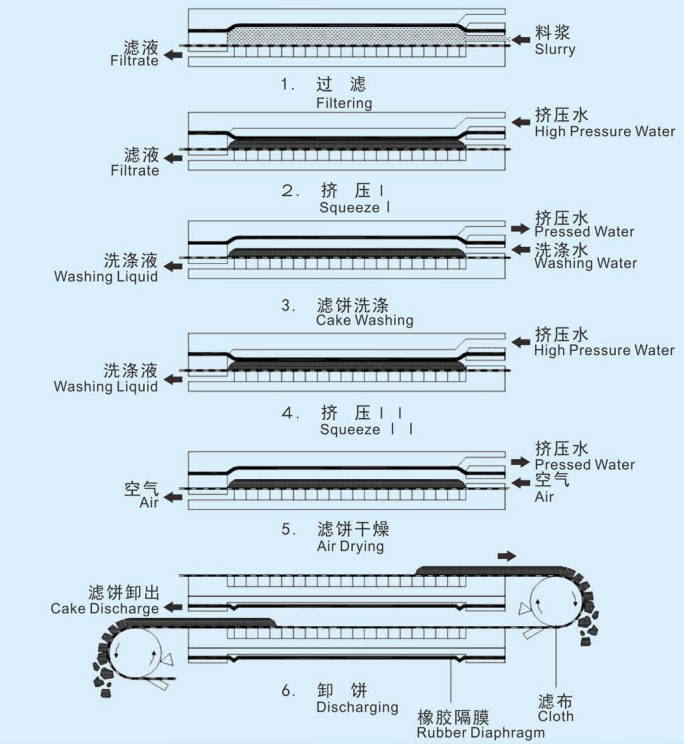

HDLY press filter can separate solid form liquid efficiently and automatically;its main four steps are feed-in, diaphragm squeeze, cake washing and air drying.

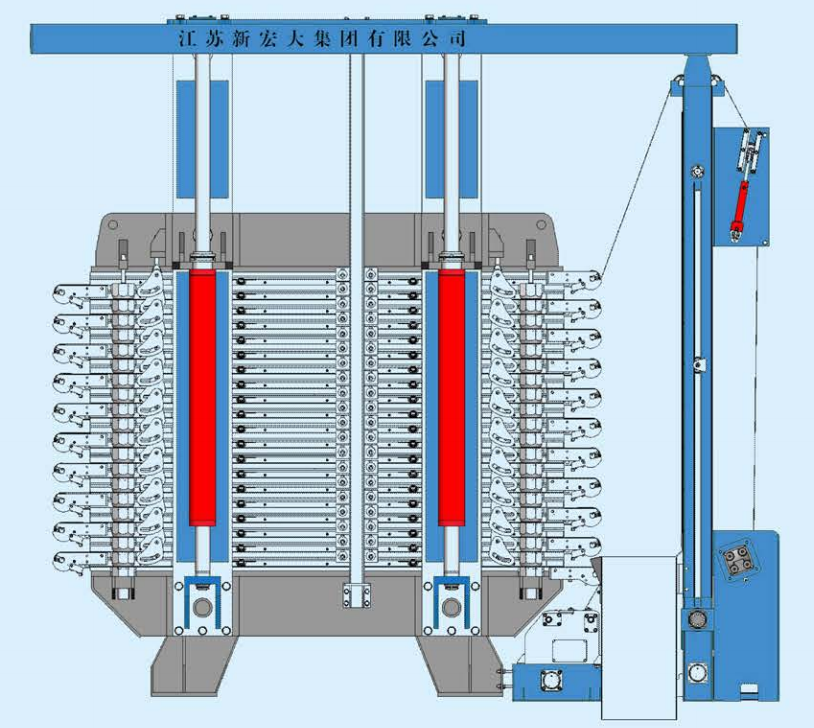

Filter plate is designed between 2 frameshorizontally. All parts of plate assembly are pressed together during filtering and then opened for cake discharging.

Filter Plate assembly is closed and opened by hydraulic cylinder.

Filter cloth runs between frames, and cakescan form on either side of cloth. The clothis counter washed automatically. When the other surface of cloth is under filtering, the residual solid particles from last cycle will be counter washed out.

After one cycle finish, the cloth is driven forward to carry out cake. After cake is discharged, a new cycle begins. The run of cloth will discharge cake from filter, and meanwhile wash with high pressure water from twoends. Filter cloth is drivenby hydraulic motor. The tension device of cloth works when frame assembly opens or closes.

Slurryenters filter chamber throughmanifold pipe. Washing water and compressed air enter through the same pipeline. After feeding, blow off valve is used todrain all from manifold pipe. The manifold pipe is located onthe inlet side. (Inlet is on the left side of drive unit).

The high pressure water is pumpedby a multistage centrifugal pump to the distribution pipes on the top of diaphragm. When squeezing stage finish, water returns the high pressure station through the same pipeline.

The operation of filter press is automatically controlledby control panel. There are display, operator interface, switch and operating buttons on control panel, which is easy to regulate and watch the circulating processes.

5. Squeezing and filtering principle

5.1 filtering process

When frame assemblies close, slurrygoes through pipe to each filter chamber. Filtrate penetrate cloth to the filtrate chamber, then reach the filtrate flexible tube, and finally the filtrate is drained out by filtrate header.

5.2 first squeeze

The high pressure water is pumped to diaphragmtop through flexible pipe, to squeeze the diaphragm. Then the cake forms between diaphragm and cloth, and the filtrate is squeezed out of cake.

5.3 washing (optional)

Wash liquid is pumped to filter chamber through the samemanifold pipe of slurry. Since the washing liquid fill the chamber fully and thediaphragm is lifted to extrude the high pressure water on top of diaphragm. Wash liquid flows to discharge pipe by passing filter cake and filter cloth.

5.4 second squeeze

After washing, some left wash liquid in chamber has to be extruded out by the same way as first squeeze.

5.5air drying

Filter cake, is dried by compressed air. Air goes to filter chamber through manifold pipe, fill up the chamber to raise diaphragm and then discharge out. Air through cake can reduce moisture content to best degree, and also empty the filtrate chamber.

5.6 cake discharge

After dry process is completed, frame assemblies open, and cloth driveunits start running.The filter cake on cloth will bedischarged from the both ends of filter.

4 processes (short processes) do not include washing and 2nd squeeze.

6. Figure for filter operation

7. Figure for frame assembly close

8. Figure for frame assembly open

|