Horizontal Rubber Belt Filter

Technical features:

1. The wet parts with slurry can be made by non-metallic materials, with high corrosion resistance and wide applications.

2. No scaling inside the flow-guide vacuum box; low resistance; high filtering efficiency and better washing by multi-stage countercurrent.

3. Automatic centering of cloth during operation

4. Excellent cloth recovery: sprayers on cloth sides are equipped to reduce blocking of cloth.

5. High capacity: the cake thickness can be adjusted in accordance with slurry characteristics, from 3mm to 100mm thick.

6. High adaptability: fast filtering can be done for thin cake.

7. New design of grooves and holes on the belt: it optimizes draining of filtrate and low moisture in the cake

8. Long service life, easy operation and low maintenance cost.

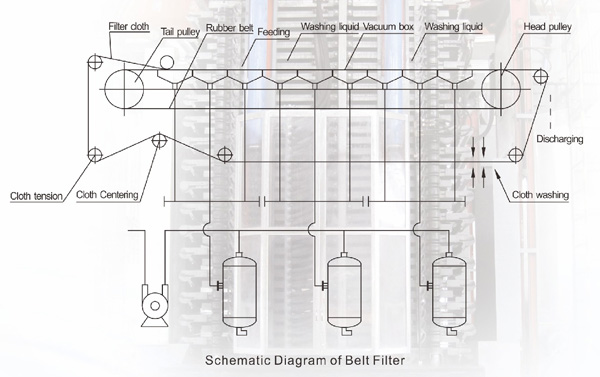

Schematic Diagram of Belt Filter

Specification and Model of Belt Filter

|

Belt Width(mm)

|

1000

|

1500

|

2000

|

2500

|

3000

|

3500

|

4000

|

|

Filter Length(mm)

|

Filter Area(㎡)

|

|

8000

|

8

|

12

|

15

|

|

|

|

|

|

10000

|

10

|

15

|

20

|

|

|

|

|

|

13000

|

|

20

|

26

|

33

|

|

|

|

|

16000

|

|

|

32

|

40

|

|

|

|

|

19000

|

|

|

38

|

48

|

54

|

|

|

|

22000

|

|

|

|

55

|

66

|

77

|

|

|

25000

|

|

|

|

|

75

|

98

|

100

|

|

28000

|

|

|

|

|

84

|

98

|

112

|

|

31000

|

|

|

|

|

93

|

110

|

124

|

※The filter model can be selected according the above table or also can be designed according to the requirement of customer.

|